How Membrane Switches Supply Smooth Operation in Extreme Environments

How Membrane Switches Supply Smooth Operation in Extreme Environments

Blog Article

Membrane Changes Explained: A Comprehensive Guide to Their Benefits

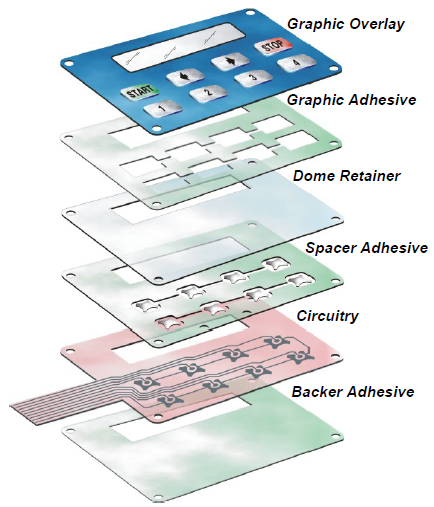

Membrane switches represent a sophisticated and versatile solution for developing interface throughout a variety of industries. Their multilayered style not just makes certain performance via simple stress but additionally offers significant advantages, such as toughness and customization. As markets significantly look for reliable and reliable control interfaces, comprehending the specific advantages and applications of membrane layer switches comes to be necessary. The intricacies of their layout and application existing special difficulties that benefit better examination. What aspects should be considered to totally leverage their potential in modern applications?

What Are Membrane Layer Switches?

When pressure is related to the membrane layer switch, the layers make get in touch with, completing an electrical circuit. This basic device permits a large range of applications, from consumer electronics to industrial machinery. Membrane buttons are usually designed to be resistant and water resistant to dirt and pollutants, making them ideal for environments where sturdiness is essential.

Furthermore, the adaptability of the products used in membrane layer switches promotes cutting-edge designs that can satisfy different shapes and measurements. This adaptability adds to their appeal in varied fields, including clinical gadgets, automobile controls, and home devices. In general, membrane changes represent an essential element in modern-day interface modern technology, connecting the space in between customers and digital systems.

Trick Advantages of Membrane Layer Buttons

Amongst the myriad of individual interface choices available, membrane changes stand apart for their unique combination of advantages. One of the main benefits is their compact and lightweight layout, which permits integration into a variety of gadgets without adding considerable bulk. This is especially advantageous in applications where space is limited.

Furthermore, membrane layer changes offer toughness and resistance to environmental variables. They are usually created with products that can endure wetness, dust, and numerous chemicals, making them appropriate for severe conditions. This toughness contributes to a longer life expectancy contrasted to traditional mechanical buttons.

An additional substantial benefit is the adaptability in customization. Membrane layer buttons can be printed with different graphics, shades, and textures, permitting customized layouts that satisfy details branding or useful demands. This versatility prolongs to the variety of layers and circuit alternatives, providing designers with numerous configurations.

Moreover, the tactile responses provided by some membrane layer changes improves individual experience, making them a lot more user-friendly to operate. The ease of cleaning and maintenance even more solidifies membrane buttons as a useful choice in both consumer and commercial applications. Generally, these essential advantages make them a recommended remedy for numerous developers and manufacturers

Applications in Different Industries

Exactly how do membrane switches locate their area across varied industries? Their versatility and performance make them integral parts in industries ranging from health care to consumer electronics. In medical gadgets, membrane switches are utilized for their convenience of cleansing and resistance to contamination, making certain health in environments where sterility is critical.

In the customer electronic devices market, more helpful hints these buttons offer smooth, easy to use interfaces that improve item appearances while preserving longevity against damage. Automotive applications gain from membrane layer switches over as well, where they are made use of in control panels and control board, using reliable efficiency in difficult problems.

Furthermore, industrial machinery utilizes membrane layer switches for control board due to their effectiveness, capability to hold up against rough environments, and personalized designs that satisfy certain functional demands. The food market leverages membrane layer buttons for their convenience of use and resistance to spills, guaranteeing functional efficiency in busy setups.

Ultimately, the versatility of membrane switches throughout these diverse applications underscores their vital duty in modern-day innovation, improving customer interaction while fulfilling industry-specific needs. Their continued development guarantees further combination into arising fields and ingenious items.

Style and Personalization Options

The design and modification choices readily available for membrane layer switches are crucial for tailoring user interfaces to meet details customer needs and visual choices. These switches can be made in different forms, sizes, and layouts, enabling smooth combination into varied applications. The adaptability in style implies that producers can create unique user interfaces that enhance functionality and preserve brand name identity.

Custom graphics, appearances, and colors can be related to the surface area of the membrane switch, providing a possibility for branding and customer engagement. Furthermore, backlighting alternatives, such as LED illumination, can be integrated to enhance visibility in low-light problems, hence improving capability.

Practical components can additionally be personalized, including responsive responses and actuation pressure, which can be adapted to fit different individual interactions. The option of materials, such as polyester or polycarbonate, permits for variants in toughness and environmental resistance, dealing with the details needs of various industries.

Inevitably, the comprehensive layout and customization capacities of membrane layer switches enable companies to create visually attractive and user-friendly interfaces, guaranteeing that their products fulfill both visual and useful demands effectively. Membrane Switches.

Considerations for Implementation

Applying membrane layer changes needs careful consideration of different variables to make sure optimum performance and user experience. One of the main considerations is the desired application environment. Variables such as direct exposure to wetness, extreme temperatures, and chemical other materials can dramatically influence the button's efficiency and durability. Choosing materials that withstand these problems is important.

Another important facet is the switch's design and format. Guaranteeing that the responsive feedback and actuation force straighten with user assumptions enhances use. Conducting individual screening can supply important insights into the optimal layout.

In addition, compatibility with electronic parts have to be analyzed. The button's circuitry need to line up with the overall system design, ensuring reputable signal transmission and reducing interference.

Furthermore, manufacturing methods and expenses ought to be reviewed. The selection in between custom designs and standard models can affect both budget and lead time.

Finally, think about maintenance and fixing. Membrane buttons might require particular cleansing and treatment treatments to preserve their appearance and performance in time. By addressing these factors to consider, companies can execute membrane layer switches that satisfy their operational needs while offering a favorable individual experience.

Conclusion

In final thought, membrane layer switches represent a versatile and resilient control interface appropriate for a broad array of applications throughout multiple industries. Membrane Switches. As technology continues to develop, the significance of membrane layer buttons in contemporary tools remains substantial, using both performance and visual allure.

Membrane layer switches over represent a advanced and functional solution for creating customer interfaces throughout a variety of industries.Understanding the essential components of modern-day digital interfaces, membrane layer buttons are a type of customer interface tool that are composed of versatile, slim layers of material. In general, membrane layer changes stand for an important component in contemporary individual interface technology, connecting the gap between customers and digital systems.

Amongst the myriad of customer interface alternatives readily available, membrane changes stand out for their distinct combination of advantages.The link design and modification options readily available for membrane buttons are essential for customizing interfaces to satisfy certain individual requirements and aesthetic choices.

Report this page